Description

Carboxymethylcellulose, first discovered in Germany and then spread to the United States and then to other Western countries, is widely used in both industrial and food grades. For economic reasons, this material has received special attention in recent years and major advances in technology have been made from this product. These advances have made it possible to use carboxymethylcellulose in various industries such as food, pharmaceuticals, detergents, paints, resins and adhesives, textiles, ceramic tiles, welding, cosmetics, and toxins, pesticides, etc.

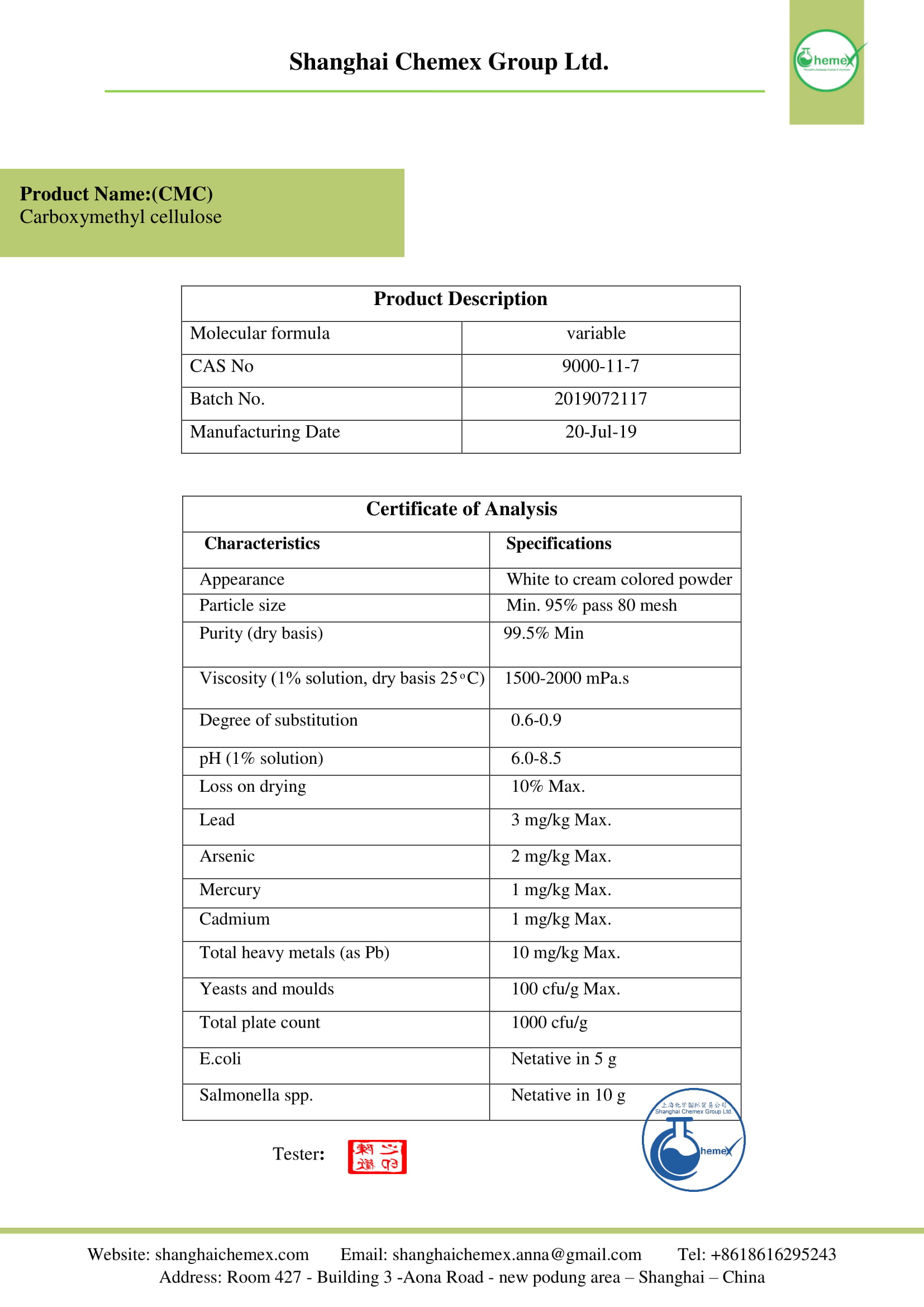

Physical and Chemical Properties:

Carboxymethylcellulose produced in addition to general features has special properties that make this product extremely efficient for various applications. These special features include the following:

- Excellent solubility in water even at low temperatures

- Thickening agent to make a relatively clear viscous solution

- Create desired rheology and viscosity properties

- Stable in a wide pH range

- Compatible with most components in the target industries

- No odor, color, or taste

- Formation of a protective layer

- Prevent the growth of crystals

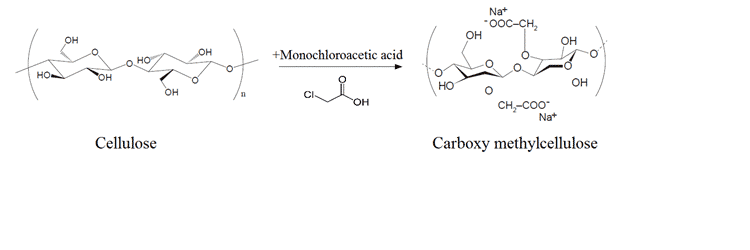

Production and Preparation of Carboxymethyl Cellulose:

Carboxymethylcellulose is a cellulose ether derived from natural cellulose sources. In the production of CMC, first cellulose is converted to alkaline cellulose using caustic soda and in the next step, carboxymethyl cellulose is formed in reaction with monochloroacetic acid.

Carboxymethyl Cellulose Uses:

Carboxymethylcellulose produced can be used in various industries, including paper, paint, glue and resin, drilling mud, detergents, and ceramic tiles. All you have to do is match your needs with the properties of carboxymethylcellulose and choose the right grade for your consumption. Some of the applications of CMC in different industries are as follows:

Food:

Carboxymethylcellulose is now one of the most essential food additives that is widely used in high-quality ice cream (to resist melting), sweets, biscuits, cakes, cookies, candies, juices, liquid beverages, dairy products, meat products, Frozen foods, instant kinds of pasta, canned and fruit compotes are used. One of the important applications of CMC is the stability and protection of proteins, especially bran protein. In addition, because this compound is a low-calorie polysaccharide, it is used in low-calorie diet foods such as diet bread, diet drinks, and diet sauces.

Pharmaceutical and Cosmetic:

Properties such as particle suspension, color retention, skin protection, uniform dispersion, dirt and stain removal, lubrication, and uniformity have led to the use of CMC in cosmetic and pharmaceutical applications.

Textile:

The properties and characteristics of carboxymethylcellulose have led to its use in the textile industry. These special properties include the ability to coordinate warp and weft, water retention and absorption, concentration in printing pastes on textiles, raw material in various fabric finishing processes, creating good adhesion to fibers, and creating strength and Wear resistance outpointed. This combination lightens the fabrics that are made of cotton and linen fibers and prevent their destruction and decay. This material is used as a raw material during the printing process, especially on silk fabrics.

Paint and Resin:

Carboxymethylcellulose can be used as a viscosity control agent in emulsion and latex paints, suspension stabilizers, and colloidal particle stabilizers. The presence of this substance in the paint causes lubrication and thus improves the movement of the brush. Another application of this material is its use of insoluble paints as a material to fill pores in porous surfaces such as gypsum wall surfaces.

Paper and Cardboard:

This material is used in the paper-making process in three parts:

- The first part is the direct use of this material in paper formulations, which increases the wear resistance, tensile strength, paper hardness, surface uniformity, and anti-brittleness.

- The second part is to use CMC for the paper surface. In this case, this material forms an adhesive layer, increases the surface strength against abrasion, improves the physical properties of the surface, surface polishing, paper resistance to organic matter, and also improves the surface flexibility against corrosion.

- The third part also includes the use of this material in coatings, which are used to improve the properties of paper.

Adhesive:

Due to its film-forming properties, good surface tension, and good adhesion (due to its long cellulose chain), it is used in the formulation of wallpaper adhesives, pulp adhesives, sandpaper adhesives, and leather adhesives.

Toxins and Pesticides:

CMC is used in the pesticide industry as a suspending agent.

Safety Information:

Carboxymethylcellulose is considered a safe substance by the FDA and WHO and its permissible consumption is 30 mg/kg per person.

First-aid measures:

- Eye Contact: In case of contact with the eyes, immediately flush the eyes with plenty of water.

- Skin Contact: Remove this material from the skin with plenty of soap and water.

- Inhalation: Remove to fresh air immediately. If not breathing, give artificial respiration.

- Ingestion: Do not induce vomiting. Get medical aid immediately. Call a poison control center.

Packing and Storage:

C.M.C is a moisture absorber, it is packaged in laminated bags or multi-walled paper bags to prevent light and moisture from penetrating and is stored in a cool, dry place.

Reviews

There are no reviews yet.